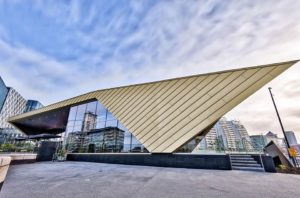

One of London’s largest blue roof developments, requiring exceptional collaboration and workmanship to ensure it stands the test of time, won Tilbury Contracts the Innovation category at the UK Roofing Awards 2018.

Built on the site of a 1930s Dylon textile dying factory in Lower Sydenham, this 1.1 hectare Crest Nicholson development features 223 apartments, retail space and a creche for 80 children. Working alongside Tilbury Contracts and architect Scott Brownrigg, Axter provided waterproofing designs for the central podium, green roofs and blue roofs.

Complexity

With a total area of 0.7 hectares, Dylon Works represents one of the biggest blue developments in London. One blue roof of 800 sqm relies on a single restricted rainwater outlet to achieve the required flow rate for the site, meaning that the site is actively contributing to protecting the waterways of England, as the total run off for the project is limited to 10 l/s. The design had to be modelled over a 300-year period, taking in to consideration likely climate change and predicted peak rainfall events. The roof is also bio-diverse, contributing to the local ecosystem, and has a fully integrated PV system that provides the majority of the electricity for the occupants.

Other challenges

Axter had to develop a solution that enable the scaffolding to be installed and taken down, prior to completion of the main waterproofing works. This involved the use of our Starcoat PMMA system for a flame-free application, once the doors where installed.

Workmanship

Axter’s Wilotekt-Plus hot melt system was used as the vapour control layer (VCL). This provided an extremely robust working platform that allowed the superstructure and external cladding of the building to be installed, prior to the installation of the waterproofing system. On top of the VCL, there are two layers of 110 mm Hytherm ADH insulation boards that achieve a target u-value of 0.10—again adding to the high performance of the building—over which a 3 mm self-adhesive bituminous membrane and 4 mm root resistant cap sheet was installed. The system was visually inspected throughout installation and then tested using a unique differential pressure testing method to ensure that the roof was watertight, prior to the installation of the 85mm blue roof system, and the bio-diverse roof finishes on top of that. Axter was involved with the project from planning through to completion, having first started working alongside the architect, Scott Brownrigg, in 2015. This collaborative approach ensured there were no NHBC compliance issues and that all the waterproofing details were designed correctly and in accordance with the British Standards. Working closely with Crest Nicholson, Axter ensured the roof was installed to the highest possible standards, with site inspections at least once every two weeks to enable any issues to be quickly resolved.What Axter says

Our mission is to protect buildings and people from the elements by designing and manufacturing the highest quality waterproofing membranes, while delivering an ‘above and beyond’ service that instils trust in our customers and positions us as a premium yet cost effective provider.

At a glance

- Project: Dylon Works

- Roofing Awards 2018: Winner of Innovation category

- Client: Crest Nicholson

- Location: London Borough of Bromley

- Roof covering: Blue Roof

- Architect: Scott Brownrigg

- Roofing Contractor: Tilbury Contracts

- Product Supplier: Axter

About Tilbury Contracts

Tilbury Contracts, which has been trading since 1975, is an approved contractors for most of the leading membrane manufacturers and suppliers and combine the use of the best products with its own qualified and trained applicators to ensure the best possible solution for customer needs.